What is a rubberized cork sheet and how is it composed?

2025-09-02 17:04:17

A rubberized cork sheet is an inventive fabric that combines the best properties of common stopper and manufactured elastic. This flexible composite fabric is made by mixing finely ground plug particles with elastic compounds, regularly nitrile elastic, and at that point compressing the blend into sheets or rolls. The result is a interesting item that offers the compressibility and versatility of stopper with the upgraded solidness, adaptability, and fixing capabilities of elastic. Rubberized plug sheets are composed of roughly 70-80% stopper granules and 20-30% elastic, in spite of the fact that the correct proportions can change depending on the particular application necessities. This composition permits the fabric to keep up cork's common properties such as warm separator and vibration hosing whereas profiting from rubber's versatility and resistance to oils, chemicals, and weathering. The combination of these two materials makes a predominant elastic stopper gasket fabric that finds broad utilize in different businesses, from car to aerospace.

How is Natural Cork Combined with Rubber for Enhanced Performance?

The process of combining natural cork with rubber to create rubberized cork sheets involves several sophisticated steps:

Cork Granulation

Natural plug bark is to begin with ground into fine particles of shifting sizes. This granulation prepare permits for superior integration with the elastic compound and guarantees a uniform conveyance all through the last product.

Rubber Compounding

Synthetic elastic, regularly nitrile elastic due to its great oil and fuel resistance, is arranged with different added substances to upgrade its properties. These added substances may incorporate plasticizers, cancer prevention agents, and curing agents.

Mixing and Blending

The stopper granules and elastic compound are altogether blended in expansive mechanical blenders. This arrange is significant for accomplishing a homogeneous mix that will result in reliable properties all through the sheet.

Sheet Formation

The cork-rubber mixture is then fed into a calendar or extruder to form sheets of the desired thickness. During this process, the material is subjected to heat and pressure, which helps to bond the cork and rubber components.

Vulcanization

The formed sheets undergo vulcanization, a curing process that uses heat and pressure to create cross-links between the rubber molecules. This step is essential for improving the material's strength, elasticity, and resistance to deformation, making it an ideal rubber cork gasket material.

Finishing

After vulcanization, the rubberized plug sheets may be advance handled through operations such as cutting, slitting, or surface medicines to meet particular item requirements.

This fastidious generation handle comes about in a fabric that synergizes the beneficial qualities of both stopper and elastic. The characteristic plug gives great compressibility and recuperation, whereas the elastic improves adaptability, tear resistance, and fixing capabilities. The combination makes a rubberized plug sheet that beats numerous conventional gasket materials in different applications.

Key Advantages: Flexibility, Tear Resistance, and Waterproofing

Rubberized cork sheets offer a unique set of advantages that make them indispensable in many industrial and commercial applications. Let's explore the key benefits that set this material apart:

Unparalleled Flexibility

The consolidation of elastic into the plug network essentially upgrades the material's adaptability. This expanded pliability permits rubberized plug sheets to acclimate to unpredictable surfaces and adjust to energetic situations where temperature variances and mechanical stresses are common. The adaptability of these sheets guarantees a tight seal indeed in applications with surface flaws or those subject to vibration and movement.

Superior Tear Resistance

One of the most striking advancements that elastic brings to stopper is expanded tear resistance. Whereas characteristic stopper can be inclined to disintegrating or breaking beneath certain conditions, the elastic component in rubberized plug sheets gives fortification against tearing and part. This upgraded strength makes the fabric perfect for utilize in high-stress situations where conventional plug might fail.

Effective Waterproofing

The combination of cork's common water resistance and rubber's impermeable nature comes about in a fabric with amazing waterproofing properties. Rubberized stopper sheets can successfully anticipate water entrance in different applications, from building development to marine situations. This waterproofing capacity, coupled with the material's resistance to oils and numerous chemicals, makes it an perfect choice for fixing and gasketing in assorted mechanical settings.

Compression Set Resistance

Rubberized cork sheets exhibit impressive compression set resistance, meaning they can maintain their sealing properties even after prolonged periods under compression. This characteristic is crucial for applications where long-term performance is required, such as in automotive gaskets or industrial machinery seals.

Thermal and Acoustic Insulation

The inherent insulating properties of cork are preserved in rubberized cork sheets, offering excellent thermal and acoustic insulation. This makes the material valuable in applications where temperature control or noise reduction is essential, such as in HVAC systems or automotive interiors.

Chemical Resistance

Depending on the sort of elastic utilized in the composition, rubberized stopper sheets can offer resistance to a wide extend of chemicals, oils, and solvents. This chemical resistance is especially useful in mechanical applications where presentation to cruel substances is common.

Vibration Dampening

The characteristic vibration-absorbing qualities of plug, combined with the versatility of elastic, make rubberized plug sheets fabulous for hosing vibrations. This property is profitable in applications extending from apparatus mounts to car components, where diminishing vibration can make strides execution and longevity.

These key advantages make rubberized cork sheets a versatile and high-performance material for a wide range of sealing and gasketing applications. The unique combination of flexibility, tear resistance, and waterproofing, along with other beneficial properties, positions rubberized cork as a superior choice for many industrial and commercial uses.

Common Applications: Gaskets, Underlayment, and Industrial Uses

The versatility of rubberized cork sheets has led to their widespread adoption across various industries. Let's explore some of the most common applications where this material excels:

Gaskets and Seals

One of the primary uses of rubber cork gasket material is in the production of high-performance gaskets and seals. These are essential components in many mechanical systems, providing crucial sealing between two surfaces to prevent leakage of fluids or gases. Rubberized cork gaskets are particularly well-suited for applications in:

- Automotive industry: Engine oil pans, valve covers, and transmission pans

- Industrial machinery: Flanges, pump housings, and compressor seals

- Electrical equipment: Transformer boxes and switchgear enclosures

- Plumbing systems: Pipe flanges and valve seals

Underlayment in Construction

In the construction industry, rubberized cork sheets serve as excellent underlayment material for various flooring types. The benefits in this application include:

- Sound insulation: Reducing impact noise and improving acoustics in multi-story buildings

- Thermal insulation: Enhancing energy efficiency by minimizing heat transfer through floors

- Moisture barrier: Protecting subfloors from potential water damage

- Comfort: Providing a slight cushioning effect for improved walking comfort

Industrial Uses

The unique properties of rubberized cork sheets make them valuable in various industrial applications:

- Vibration isolation: Used in machinery mounts and anti-vibration pads to reduce equipment noise and vibration

- Electrical insulation: Applied in transformers and other electrical equipment as an insulating material

- Chemical-resistant linings: Utilized in storage tanks and processing equipment handling corrosive substances

- Marine applications: Employed in boat decking and hatch covers for its water resistance and non-slip properties

Automotive Components

Beyond gaskets, the automotive industry uses rubberized cork sheets in several other applications:

- Brake and clutch pedal pads

- Interior trim components for noise reduction

- Transmission shifter bases

- Weather stripping and seals

Aerospace Industry

In aerospace applications, rubberized cork sheets find use in:

- Thermal protection systems for spacecraft

- Vibration dampening in aircraft components

- Sealing materials for fuel systems

Consumer Products

The versatility of rubberized cork extends to various consumer products:

- Cork boards and bulletin boards

- Non-slip surfaces for household items

- Coasters and placemats

- Shoe insoles for comfort and moisture absorption

The wide range of applications for rubberized cork sheets demonstrates their versatility and effectiveness in solving diverse engineering and design challenges. From critical industrial sealing applications to everyday consumer products, the unique combination of cork and rubber properties continues to find new and innovative uses across multiple sectors.

Conclusion

Rubberized plug sheets speak to a exceptional combination of common and engineered materials, advertising a special combination of properties that make them crucial in various applications. From their composition of plug granules and elastic compounds to their upgraded execution characteristics, these flexible sheets have demonstrated their worth in businesses extending from car and aviation to development and customer goods.

The key preferences of adaptability, tear resistance, and waterproofing, coupled with fabulous cover and vibration hosing properties, position rubberized plug sheets as a predominant choice for numerous fixing and gasketing needs. Their capacity to acclimate to sporadic surfaces, stand up to chemicals, and keep up execution beneath different conditions makes them an perfect arrangement for challenging designing problems.

As businesses proceed to advance and request more specialized materials, the applications for rubberized plug sheets are likely to extend advance. Their eco-friendly nature, being mostly determined from economical plug sources, too adjusts well with developing natural concerns in fabricating and construction.

For businesses and people looking for high-performance fixing arrangements or flexible materials for different applications, rubberized plug sheets offer a compelling alternative. With their interesting mix of properties and wide-ranging employments, these inventive materials proceed to play a vital part in progressing innovation and making strides item execution over numerous sectors.

FAQ

1. What thickness options are available for rubberized cork sheets?

Rubberized cork sheets are typically available in thicknesses ranging from 1mm to 10mm. Custom thicknesses can often be produced to meet specific requirements.

2. How long do rubberized cork gaskets typically last?

The lifespan of rubberized cork gaskets can vary depending on the application and environmental conditions. In general, they can last several years when properly installed and maintained.

3. Can rubberized cork sheets be used in high-temperature applications?

While rubberized cork sheets have good temperature resistance, their upper limit is typically around 120°C (248°F). For higher temperature applications, specialized formulations may be required.

4. Are rubberized cork sheets environmentally friendly?

Rubberized cork sheets are partially made from renewable cork resources, making them more environmentally friendly than many all-synthetic alternatives. However, the rubber component is typically synthetic.

Premium Rubberized Cork Sheets | LEECORK

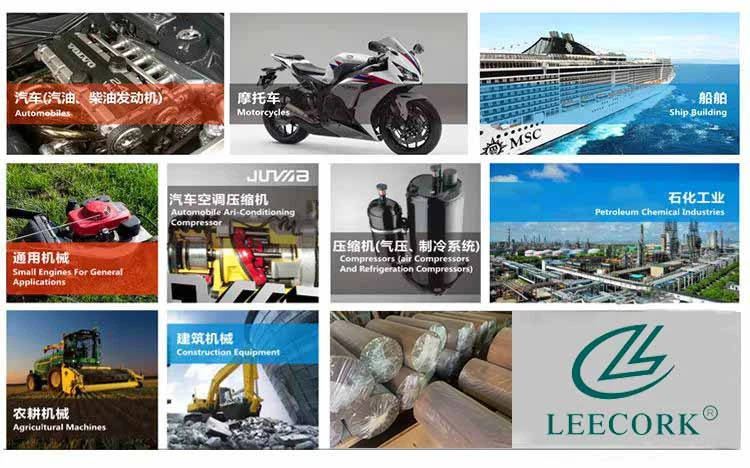

Looking for top-quality rubberized cork sheets for your industrial or commercial applications? Look no further than Xi'an Leecork Co., Ltd. As a leading manufacturer and supplier of cork products since 2002, we offer a wide range of rubberized cork sheets tailored to meet diverse industry needs.

Our rubberized cork sheets are available in various thicknesses and sizes, including standard dimensions of 1000x1000mm and 930x630mm, with custom sizes available upon request. We use high-grade nitrile rubber combined with premium cork granules to ensure superior performance in sealing, insulation, and vibration dampening applications.

Whether you need rubber cork gasket material for automotive use, underlayment for construction projects, or specialized industrial applications, our experienced team can help you find the perfect solution. We pride ourselves on serving clients from over 50 countries worldwide, including industry pioneers and leaders in their respective fields.

To learn more about our rubberized cork sheets or to request a quote, please contact us at info@leecork.com. Our knowledgeable staff is ready to assist you in selecting the ideal rubberized cork products for your specific needs, ensuring optimal performance and longevity for your applications.

References

1. Cork Institute of America. (2021). "The Properties and Applications of Rubberized Cork Composites."

2. Journal of Materials Science. (2019). "Mechanical and Thermal Properties of Rubberized Cork Sheets for Industrial Applications."

3. International Journal of Adhesion and Adhesives. (2020). "Adhesion Characteristics of Rubberized Cork in Sealing Applications."

4. Composite Structures. (2018). "Vibration Damping Performance of Rubberized Cork Sheets in Automotive Applications."

5. Materials Today: Proceedings. (2022). "Recent Advances in Rubberized Cork Sheet Manufacturing Techniques."

6. Journal of Building Engineering. (2021). "Thermal and Acoustic Insulation Properties of Rubberized Cork Underlayments in Construction."

You May Like

0Related Industry Knowledge